We started the project with our standard product design engineering approach, understanding what the customer needed, how the parts would be used, and the conditions they had to survive. ATV components face constant mud, vibration, and weather exposure, so the design had to be strong, lightweight, and reliable.

With this clarity, we moved into designing the fender and compact audio mount using the same straightforward process we follow for any complex plastic component design project.

1. Requirements Definition & Materials Selection

Our team worked closely with the customer’s R&D and engineering teams to understand how the fender flare and compact audio mount would integrate with the ATV’s existing structure. ATV components face far harsher conditions than standard automotive parts, continuous vibration, mud, water, UV exposure, fuel splashes, and sudden temperature shifts.

So our first step was to understand the load cases, mounting constraints, environmental stresses, and safety expectations for both components.

With the requirements clear, we explored engineering plastics that could survive these conditions. We evaluated materials that met FMVSS, ISO 16750-1, and ISO 14001 standards and selected grades offering:

- High impact strength (for off-road shocks on the fender)

- UV and chemical resistance

- Dimensional stability for both the fender and audio mount

- Good moldability for mass production

This gave us a strong foundation for durable, long-lasting ATV plastic component design.

2. Concept Development & Engineering Design

Next, we developed multiple concepts for the fender flare and audio mount based on established automotive component design guidelines.

For the fender flare, our design focused on:

- Geometry that extends the existing fender and provides proper tyre coverage

- Strong, impact-resistant profiles to handle debris during off-road use

- Clean mounting points that fit without drilling and stay rattle-free

- Wall thickness and draft angles optimized for smooth, cost-efficient molding

- A surface profile that reduces mud splash and prevents buildup between the flare and fender

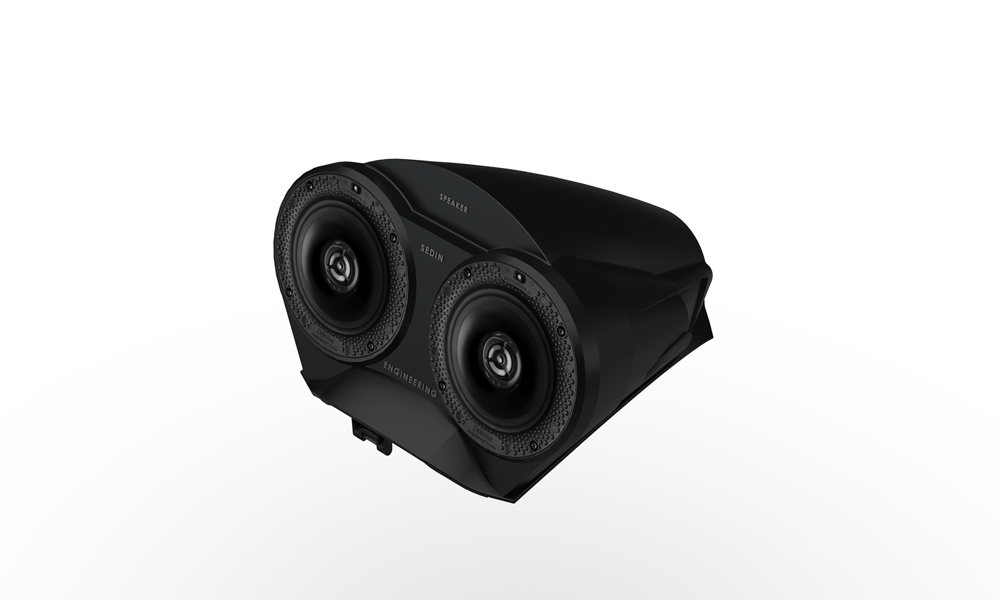

For the compact audio mount, we designed:

- A sturdy enclosure that protected the speaker system

- Water-resistant geometry to handle splashes and rain

- Vibration-isolated mounting points for better sound clarity

- Proper drainage paths to avoid moisture trapping

Both components followed strong GD&T practices to ensure accurate fitment with the ATV body.

3. DFMA, DFMEA & Design Optimization

Once the customer approved the core concepts, we moved into detailed design.

Our team applied:

- DFMA to simplify manufacturing and reduce tooling complexity

- DFMEA to identify and fix possible failure modes early

- Moldability checks to avoid issues like warpage, sink marks, or weak screw bosses

We optimized wall thickness, reinforced mounting areas, refined drainage features, and improved the overall structural integrity of both the fender flare and audio mount. These steps ensured that the components were not only functional but also easy to manufacture consistently at scale.

4. Design Iteration & Final Refinement

We designed both components with precision from the very first step, which minimized iterations and helped us arrive at a manufacturing-ready solution quickly. Our approach ensured:

- Accurate fitment with the ATV chassis

- High strength and stiffness for off-road use

- Reliable weather resistance

- Simple, error-free assembly

- Cost-efficient manufacturability

Both components were fully engineered, validated, and ready for manufacturing, meeting the high demands of real-world ATV use.

The final deliverables included 3D CAD models, 2D drawings and BOM, giving the client everything needed to move straight into manufacturing.